.jpg)

Datamatrix and DPM (Direct Part Marking)

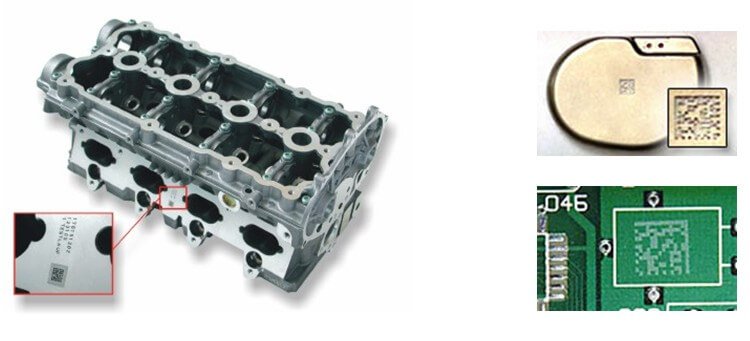

The Data Matrix Code in combination with Direct Part Marking is increasingly being recognized as an ideal means of meeting the requirements of lifetime tracking of parts in various industries and application areas. The code is standardized and thus recognized worldwide. It can be applied in a variety of ways and has a very high error tolerance. This makes it a preferred choice for marking parts, especially in the healthcare and manufacturing industries.

Typically, the code contains information such as manufacturer, part and batch number. Special optical cameras are used for reading. The Data Matrix codes can be recognized even if they are barely visible as a relief on surfaces or are painted over.

The Data Matrix Code ECC 200 is standardized in the ISO/IEC 16022 standard. ECC 200 refers to the Reed-Solomon error correction method. This allows up to 25% of the errors in the individual elements to be automatically corrected in the camera readers if, for example, parts of the code have been covered or destroyed. This is due to the fact that the information in the Data Matrix code is stored redundantly. Unlike the linear barcode commonly used in retail, the Data Matrix Code also does not require high contrasts. Relief-like surface embossing is completely sufficient for readability. The smallest surfaces are sufficient. On particularly suitable surfaces such as silicon plates, a code size of 1 square millimeter has already been realized for storing 20 characters.

Method direct application of data matrix and DPM codes:

- Inkjet process

- Laser marking with color change

- Electrochemical engraving

- Needle marking

COSYS has been working with leading direct markers in the DPM field for many years. Since July 2007, COSYS is one of 6 selected Motorola partners in Germany that exclusively distribute Motorola´s Symbol DPM product range.