Component tracking solution

Production order solution

Batch Management

Inventory Management

Data matrix and DPM (Direct Part Marking)

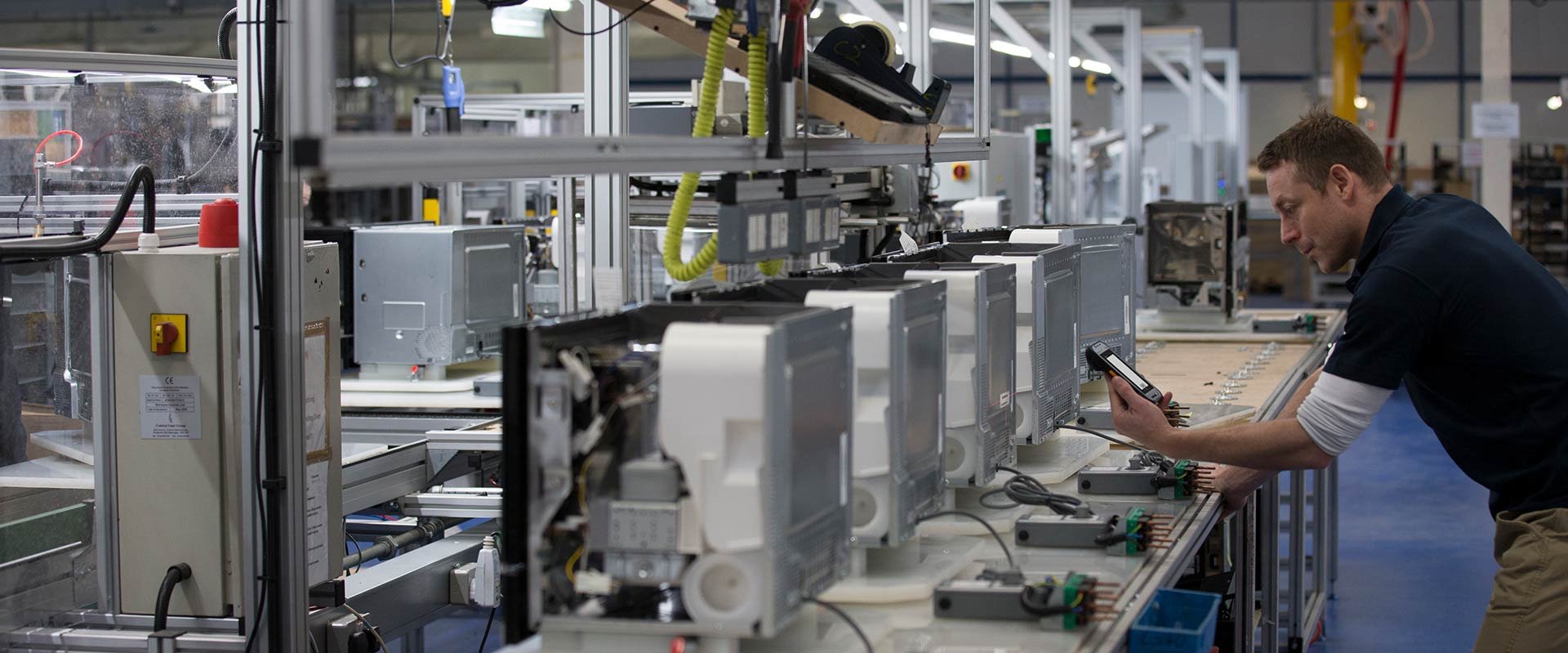

Several areas, departments and partner companies involved in the chain ensure the success of a supply chain. After the delivery of raw materials, the production area makes the start. Every logistics chain begins with the production or manufacture of its goods before moving on to the next station. Starting with the receipt of the production material, if necessary already semi-finished products, up to the finished message/shipment, the goods pass through several stages in the production area. If delays occur at one point, for example, the entire chain begins to break down.

The Manufacturing Execution Software (MES) system is described as the process-oriented, operating level of a multi-layer production management system. Often the German term Produktionsleitsystem is used synonymously. The COSYS software system is connected to this level by data integration and various interface possibilities. The mobile data acquisition of COSYS offers a permanent overview of all data during a production process, manages these data and transfers them to the downstream systems mentioned above.

Transmission via WLAN or UMTS/LTE possible

Cost and time savings thanks to optimization of warehouse logistics

COSYS Manufacturing Execution System solution provides high transparency along the production chain and more safety and direct control through the possibility of constant feedback of all production steps and direct communication with the producing workers and their mobile devices. As a result, errors and delays can be detected at an early stage or can even be completely avoided. The fewer errors that occur, the more reliably agreed delivery dates for further processing can be met. On-time production means high delivery reliability.

COSYS complete solution includes exactly this goal! Software-based systems and powerful MDE devices shape your entire production process! Through modern technology and the resulting automation, workflows can be accelerated. COSYS provides all involved persons with the view of the entire order processing in only one system and thus offers a better cooperation.

COSYS relies on modularly structured complete solutions. These solutions map all manufacturing steps and material processes. From the receipt of raw materials, to component tracking, to the supply of production workstations via kanban, to the shipping of finished parts.