Production order COSYS solution

Digital production orders are the prerequisite for more flexibility and fewer errors in production.Production order Manufacturing Execution System

Manufacturing companies are being commissioned at ever shorter notice, often the first delivery is to be made the very next day. For this purpose, it is necessary to schedule production orders into production as quickly as possible and to assign the order to the workers.

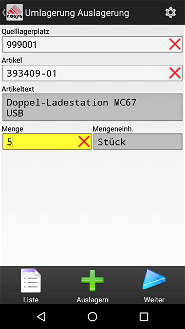

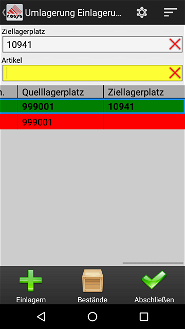

The Production Order module makes digital production a success. When an order is created in the leading ERP system, it can be assigned to employees or a group of members for processing. After calling up the production order, the required material is displayed and can be validated by means of barcode scanning. If workpieces have to be processed on machines, barcodes can also be used here for orientation and confirmation of the work step.

Overview of production orders and their prioritization

Recording of batches and serial numbers possible

Overview of required materials

Confirmation of good and scrap quantities

Direct feedback back into the PPS / ERP system

Simple order feedback and posting to machines via barcodes

Digital production orders are always up to date

Barcode capture helps identify material uniquely

Production Order Manufacturing Execution System Solutions

After a production order has been completed, further software modules can be used to prepare the goods for dispatch on a pallet or to transfer them to a production warehouse. If not only large quantities but also individual parts with serial numbers are processed, component tracking can be used to trace components with serial numbers and production batches.