Picking warehouse, production, wholesale

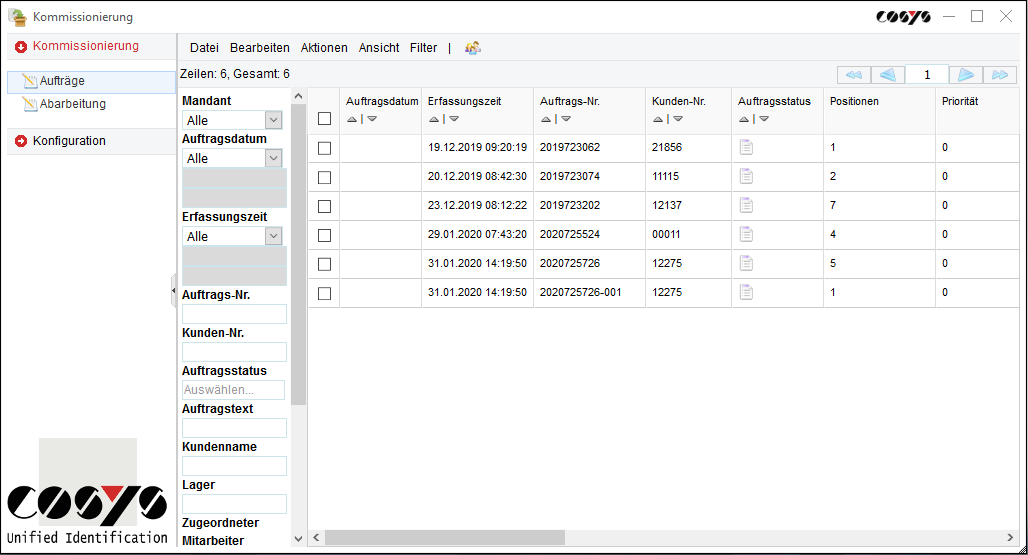

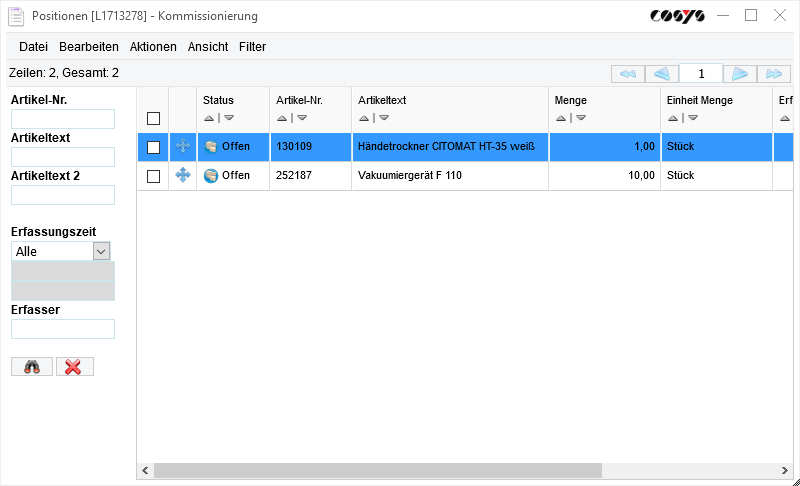

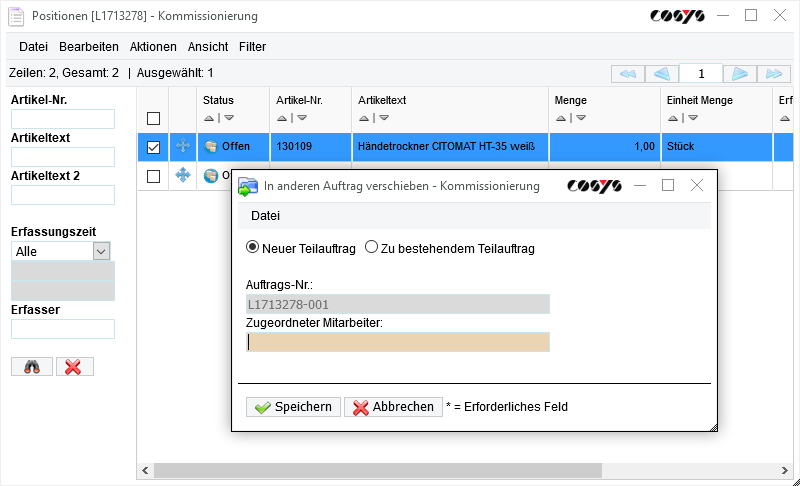

Many warehouses still work with paper-based pick lists, go with the future now and digitize your warehouses with the mobile picking software solution. Equip your employees with mobile data entry devices, so the pick lists from your ERP system flow directly to the MDE device of your employees. Data collection with MDEs ensures a transparent work process, so errors can be avoided when picking goods. You can easily assign picking orders to employees who are currently free. With COSYS WebDesk you create transparency and can see the current processing status and inform customers in time. In addition, you can split large and time-critical orders into several partial orders and thus prioritize them decisively.

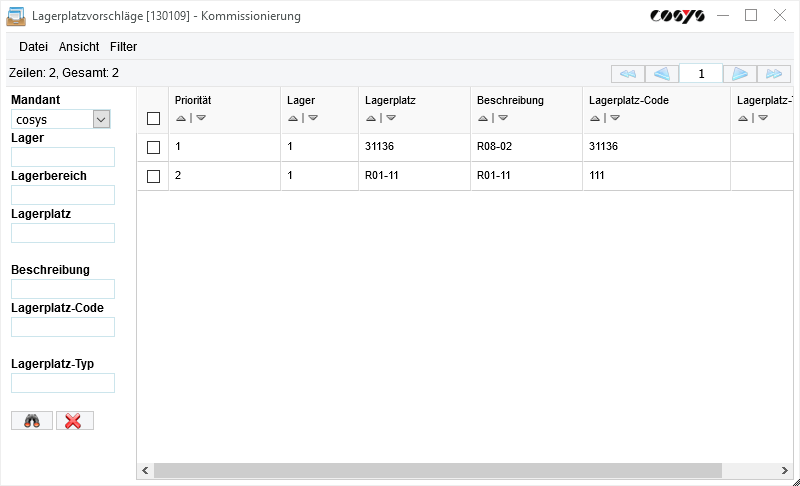

An order requires item positions from the internal warehouse, the external warehouse as well as parts from production or packing. Using COSYS systems, the order can be divided into partial orders and processed simultaneously in different warehouse departments. In parallel picking, several orders are processed in parallel. Via the warehouse control station of theCOSYS WebDesk keep an overview of the machining process.

COSYS offers the right solution for every type of picking or picking process - from software for 1-step picking to software for 2-step picking to NVE - picking to individual picking software.

Supported picking types from COSYSAll picking types have in common that during picking individual articles are assembled from a total assortment according to order specifications. Depending on the company, size and products, there are different picking methods to take advantage of as many process benefits as possible.

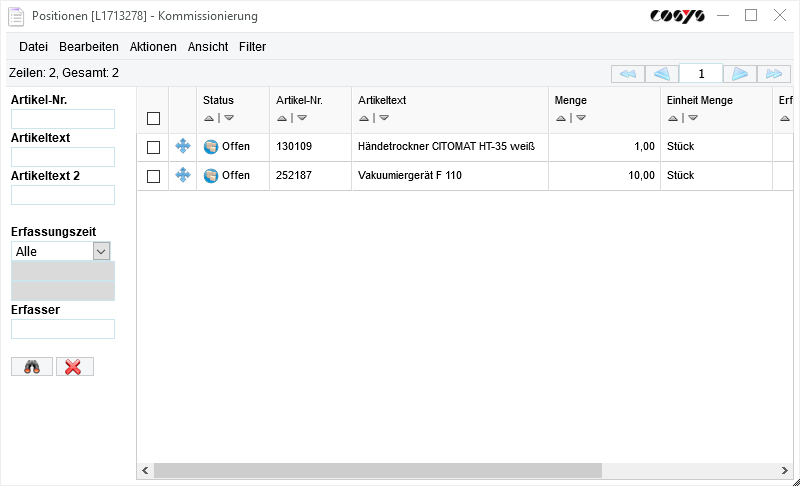

Single stage pickingSingle-stage picking basically processes one order after the other. This is either an order series of always identical requirements or a single order. The use of single-stage picking makes sense for complex goods and orders with many individual items. Even if only a few orders are processed per day and the storage area is small.

Two-stage pickingIn two-stage, multi-stage or rolling order picking, not only one order is processed, but several orders are processed in parallel or one order is divided into several orders in order to have them processed by several order pickers. Two-stage picking is also used when many orders with a small number of individual items have to be processed. The picking process is considered to be particularly efficient, but software support is absolutely necessary to avoid errors.

"Toward pick-by-MDE, pick-by-tablet and pick-by-terminal and away from errors, long processing times and pick-by-paper"

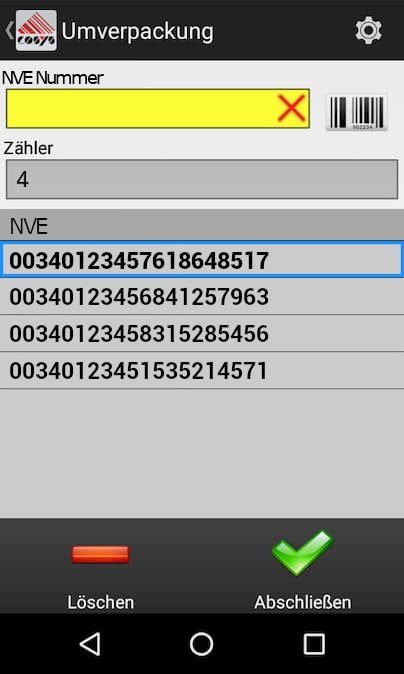

NVE PickingNVE picking is playing an increasingly important role in everyday life. In this type of picking, numbers are assigned to the packages in order to simplify logistical processes along the supply chain and in particular the supply of trading partners. This is the "Shipping unit number (NVE)". Individual packages can then be assigned to a pallet. The NVEs are thus assigned to a master NVE.

The warehouse employee starts picking goods. Depending on the process configuration, goods are directly assigned to packages and thus to NVEs or it is assigned in a second step at the end of picking.

Goods receipt is significantly simplified by means of NVE picking, as the shipping units are packed according to order or store. In order to utilize logistical resources, mixed pallets with different primary, secondary and tertiary packaging are also combined into one load carrier. This means that NVE picking can also be used for cross docking.

Picking / Picking Software Modules

COSYS Software supports you in optimizing your warehousing with flexible software modules. This allows you to create an individual solution for your picking so that your picking process runs even more efficiently. For this purpose, picking orders are digitized and sorted according to priority so that the picker can process pick lists and packages faster.

COSYS offers the right solution for every type of picking or picking process - from software for 1-step picking to software for 2-step picking to individual one-time picking software.

COSYS HardwareThe hardware used can be selected according to the individual business process, and the software does not limit the choice. Different work processes, workflows and departments may require different mobile devices. Whether the process requires a physical keyboard or the application requires fewer keystrokes and therefore a full-touch device is a better option is often easiest for operational staff to judge.

For example, forklift operators with a long-range scan engine can avoid dismounting from the forklift and thus work more productively. Pallet ID scanning also eliminates the need for further identification and verification of the pallet, as all essential information is already captured via the pallet ID.