COSYS NVE and Track & Trace solutions for the DIY industry

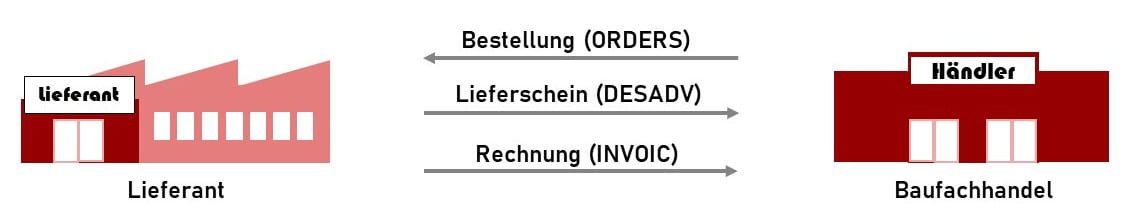

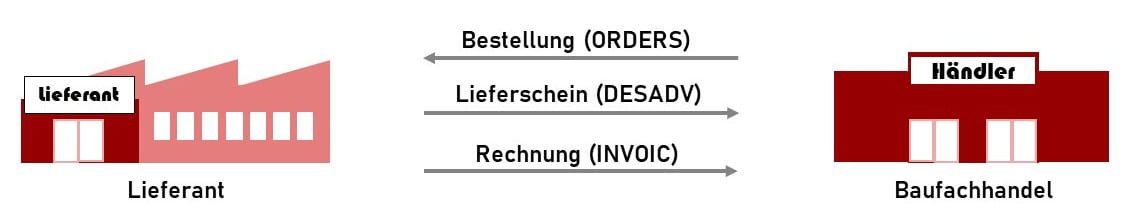

With the aim of making the supply chain in the DIY industry more efficient and automated, the BHB Association of the DIY industry has created a guideline for an electronic data exchange with NVE / SSCC. This guideline should simplify and standardize the electronic data exchange between suppliers and retailers, especially with regard to ORDERS, DESADV and INVOIC messages. Special focus is on the Despatch Advice (DESADV), which is extended by the number of the shipping unit (NVE / SSCC) to enable a consistent identification of orders, load carriers and packages with the help of the NVE. In order to achieve this, the BHB Guideline DESADV with NVE / SSCC describes precise requirements, which serve suppliers as well as retailers in the DIY industry to create a common basis for electronic data exchange and package identification.

BHB Guideline DESADV with NVE / SSCC for the DIY industry

BHB Guideline DESADV with NVE / SSCC for the DIY industry Electronic Despatch Advice DESADV

Electronic Despatch Advice DESADVElectronic data exchange between companies is becoming increasingly important. Digitization, individualization and continuing globalization mean that companies are aiming for faster and more effective processes in order to achieve a leaner supply chain. An important part of this is the use of identification and communication standards to ensure that orders and shipping notifications can be exchanged independently of software and hardware. Especially the electronic Despatch Advice Document (DESADV) is an important communication tool to inform ship-to parties about future deliveries. Information about a delivery, such as GTIN, quantity, number of packages, pallets, batches, etc. is sent to the consignee in this way. A delivery notification can contain individual items, packages or orders. Through this message, the ship-to party knows before the physical delivery when which goods were shipped and can accordingly prepare the processes in goods receipt and match the shipping notification data with the order.

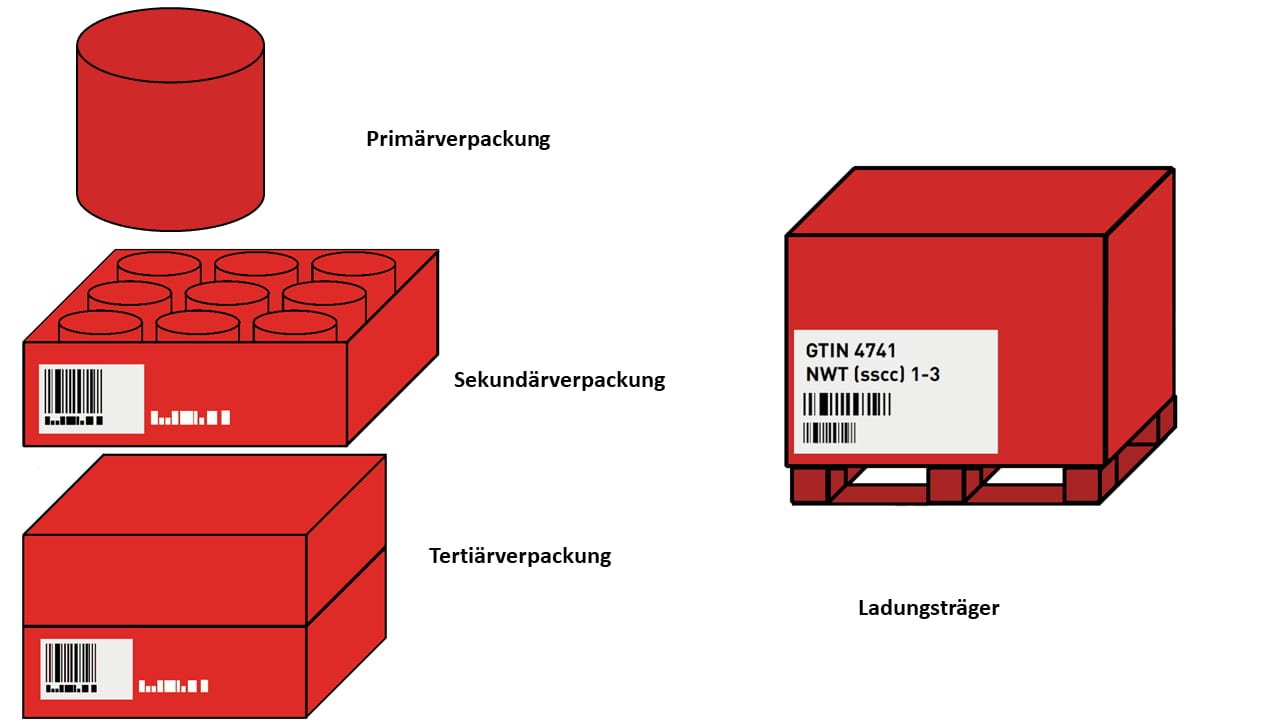

Packing of the goods

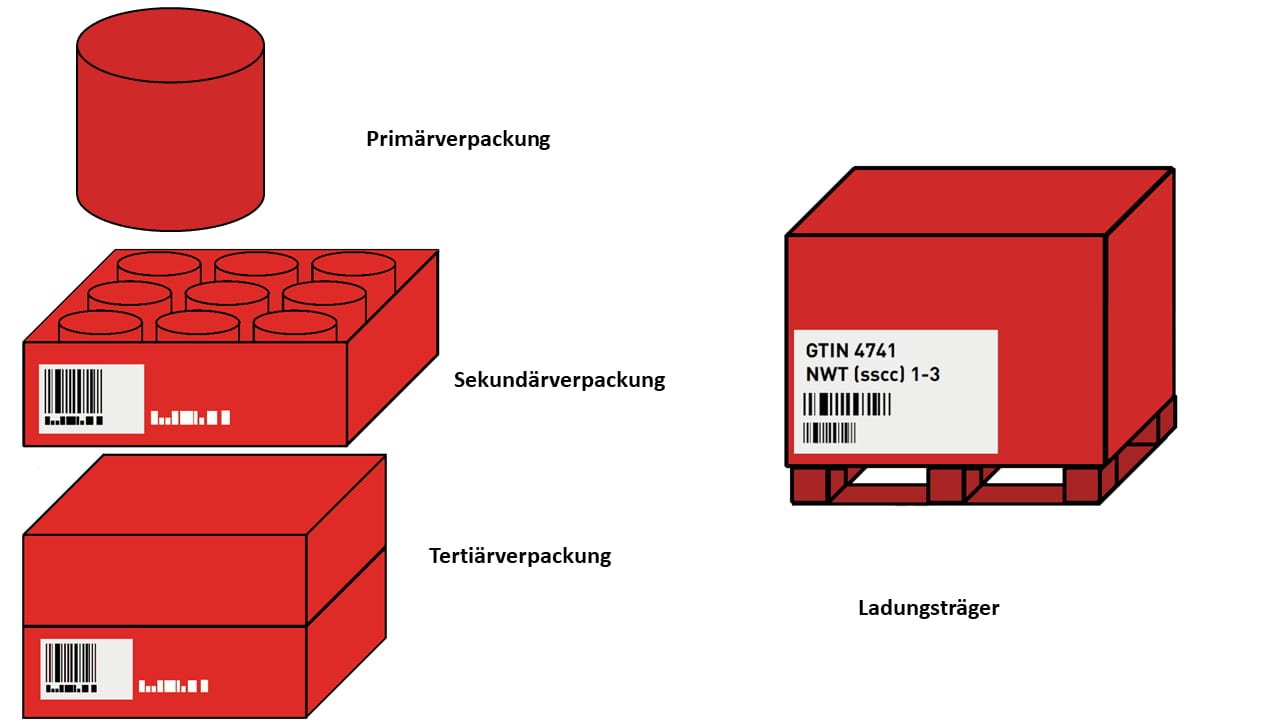

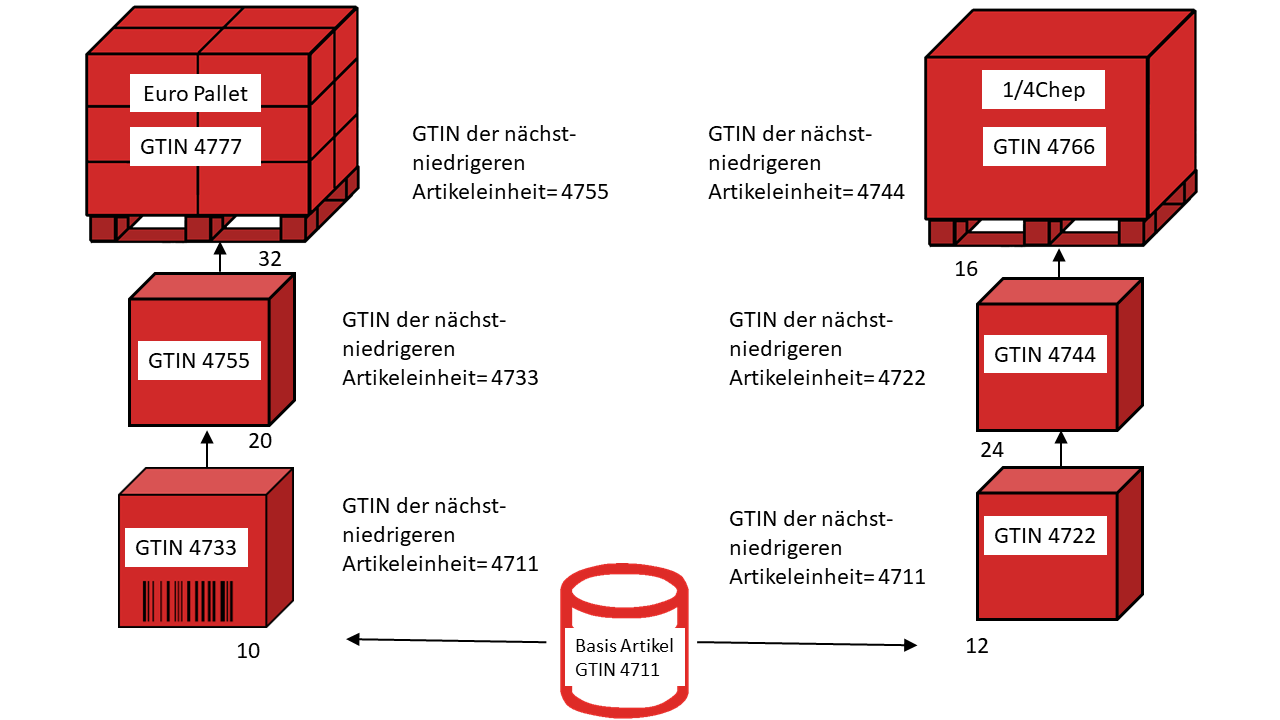

Packing of the goodsIn addition to the complete wrapping of goods, packaging also has other important tasks within the supply chain. Depending on the area of value creation, functions for production, marketing or transport must be fulfilled. Accordingly, the requirements for packaging are based on influencing factors, customer needs, legal requirements or ecological requirements. To ensure that the value chain from the producer to the consumer runs optimally, different types of packaging are used to meet the various functions.

- Primary packaging

Primary packagingen are packages that are offered to the end customer as a retail unit. Primary packagingen can also be used as additional packaging for the sales packaging.

- Secondary packaging

Secondary packagingen are packagings that facilitate handling and transport processes of goods or primary packagingen by packaging primary packagingen in further packagingen (secondary packagingen). Goods are thus protected from damage and enable safe transport. Secondary packagings can be, among other things, manageable packaging such as cartons or thermally treated wrappings of several primary packagings.

- Tertiary packaging

Tertiary packagingen are equal in functionality with secondary packaging. They are manageable packaging designed to facilitate the handling and transport of secondary packagings and also protect against damage to the goods. Secondary packagings used as sub-packagings also bring additional handling procedures in picking, when secondary packagings are picked/packed in tertiary packagings (aggregation).

- Load carrier

Load carriers serve as aids for the safe placement of goods in transport and warehousing. Like secondary packaging and tertiary packaging, their purpose is to facilitate handling and transport processes of goods, as well as to ensure safe transport by means of numerous load securing devices. Load carriers can appear in the form of pallets, containers and other cargo units.

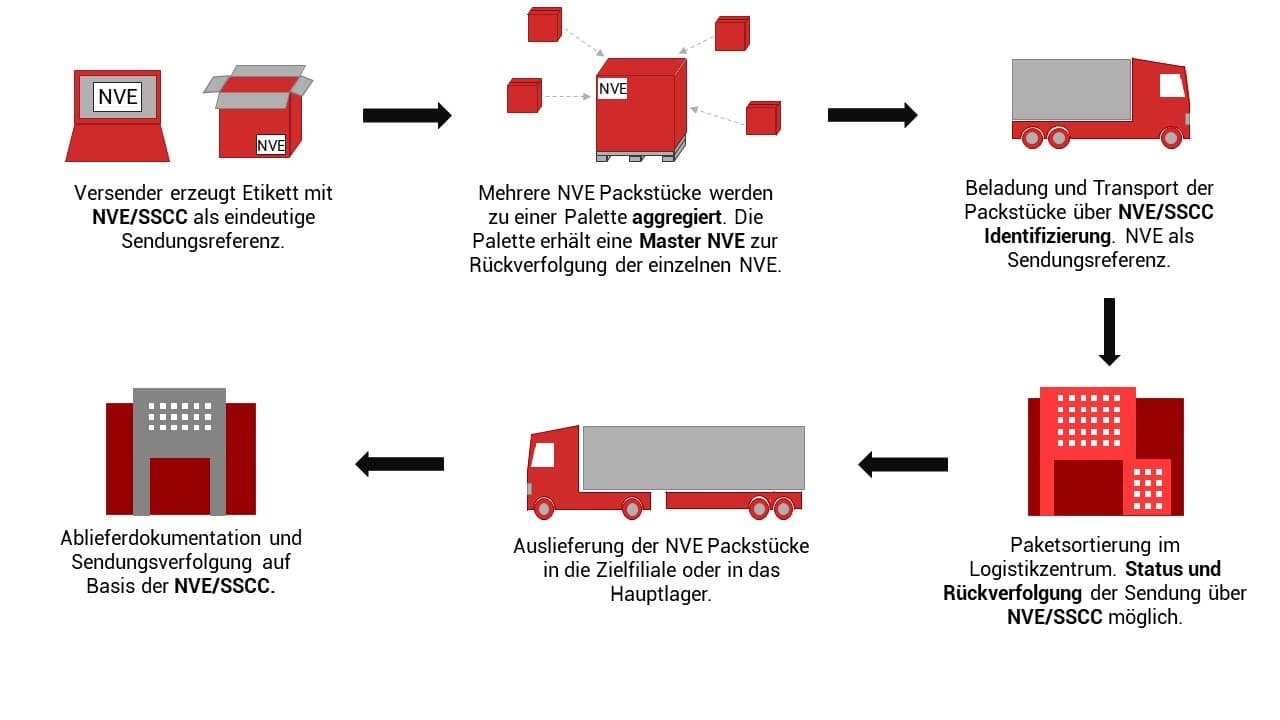

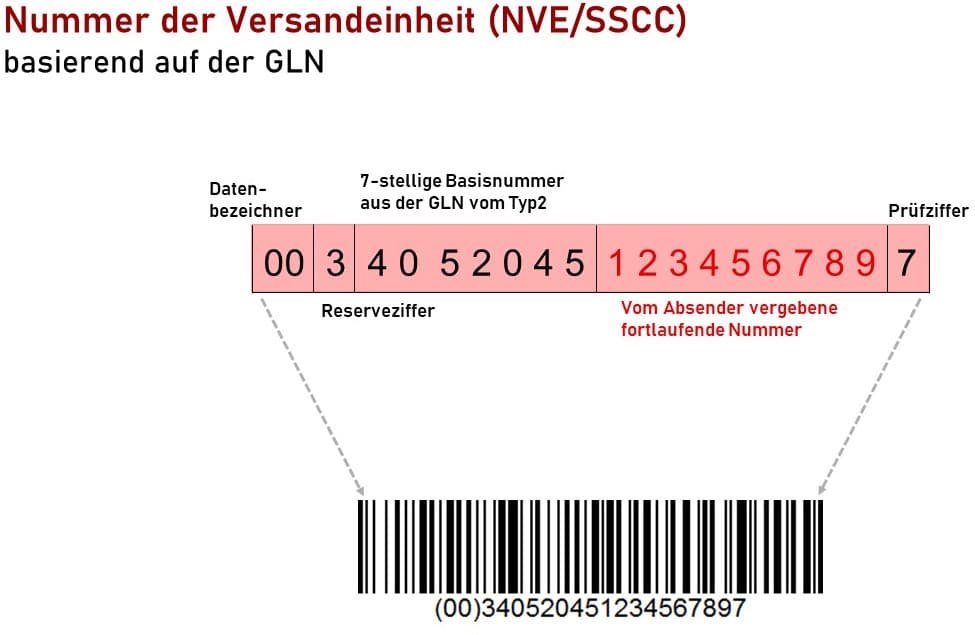

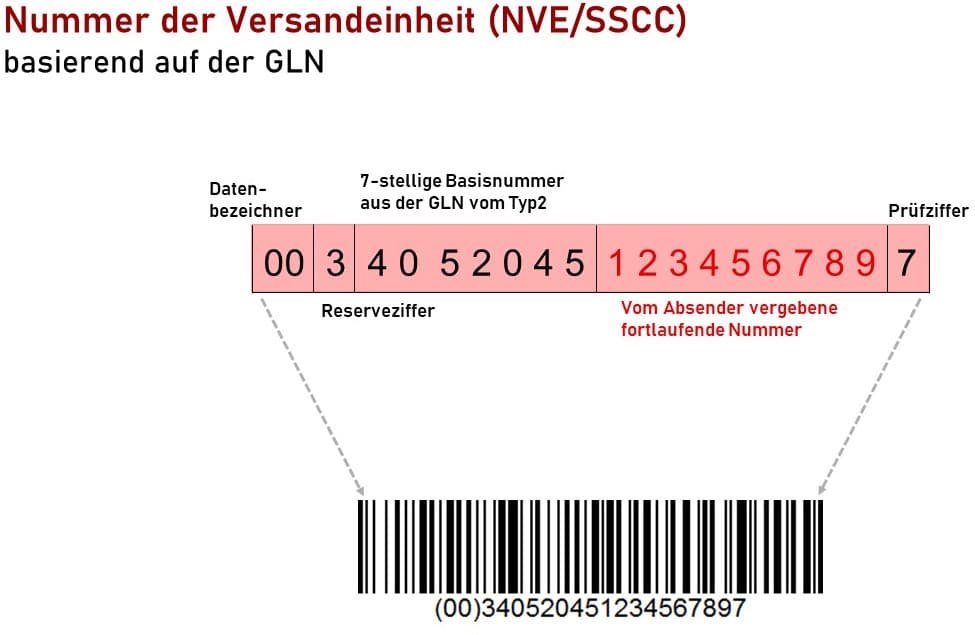

Shipping unit number NVE / SSCCTo optimize logistics processes in the DIY industry, a unique identification system is required for shippers, service providers and recipients. For this purpose, packaging units are provided with legible transport labels that contain the globally unique number of the shipping unit (NVE / SSCC). As an important component of the globally established GS1 128 logistics standards, the NVE / SSCC serves to uniquely identify logistical container units throughout the entire logistics chain. In this way, the NVE enables shipments to be tracked from the sender to the recipient (track and trace). Since the NVE is assigned once and can be used by all participants in the transport chain, it is possible for every company in the DIY sector to transfer and track shipments with NVE. To identify the shipments, transport labels are used that are applied to the respective loading equipment / packaging unit and contain the shipper, recipient and the NVE. However, before the NVE is applied to the transport label, the NVE code must first be generated by the DIY store / builders´ merchant supplier from the merchandise management system (usually ProAlpha). The shipper can then print out the NVE label, apply it to the loading equipment and transmit the NVE with the DESADV to the recipient of the goods (DIY trade, builders´ merchant). This is the only way to ensure that the consignments can be clearly assigned to the recipient.

By scanning the NVE barcode, complete documentation of storage, retrieval, picking and other transport processes can be achieved with a minimum of personnel effort. At the same time, reliability is also improved because data is matched electronically.

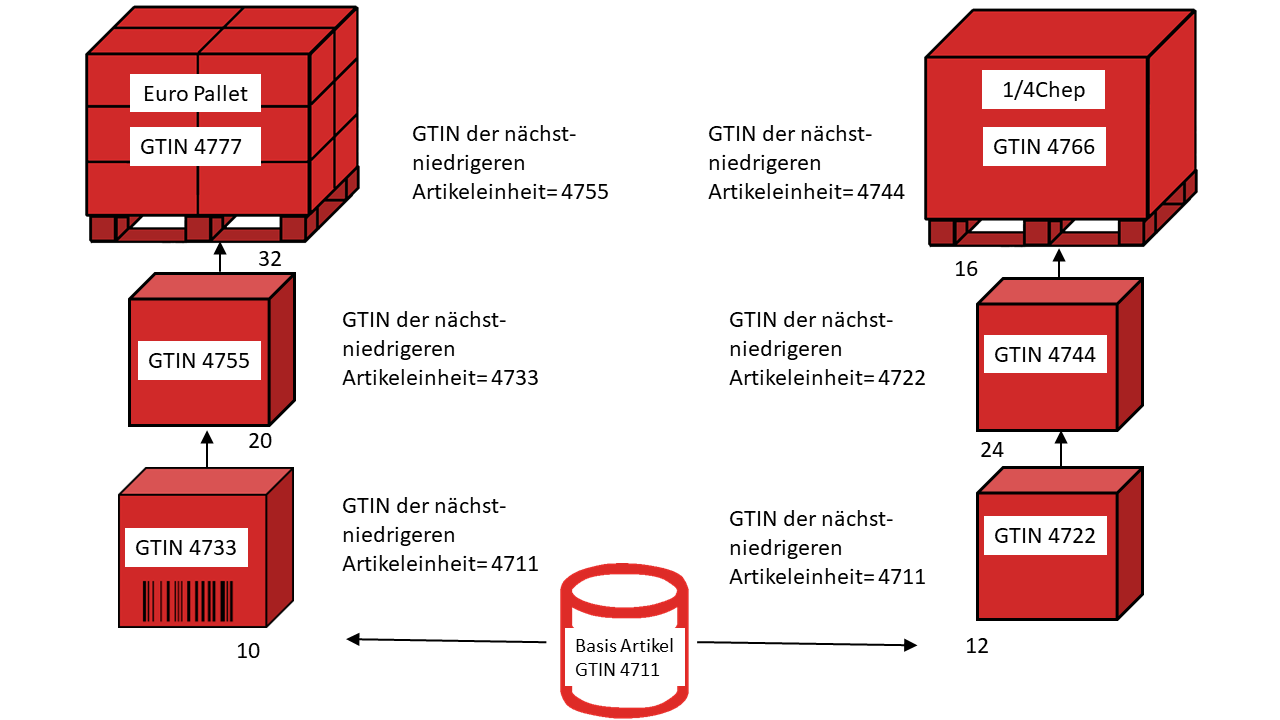

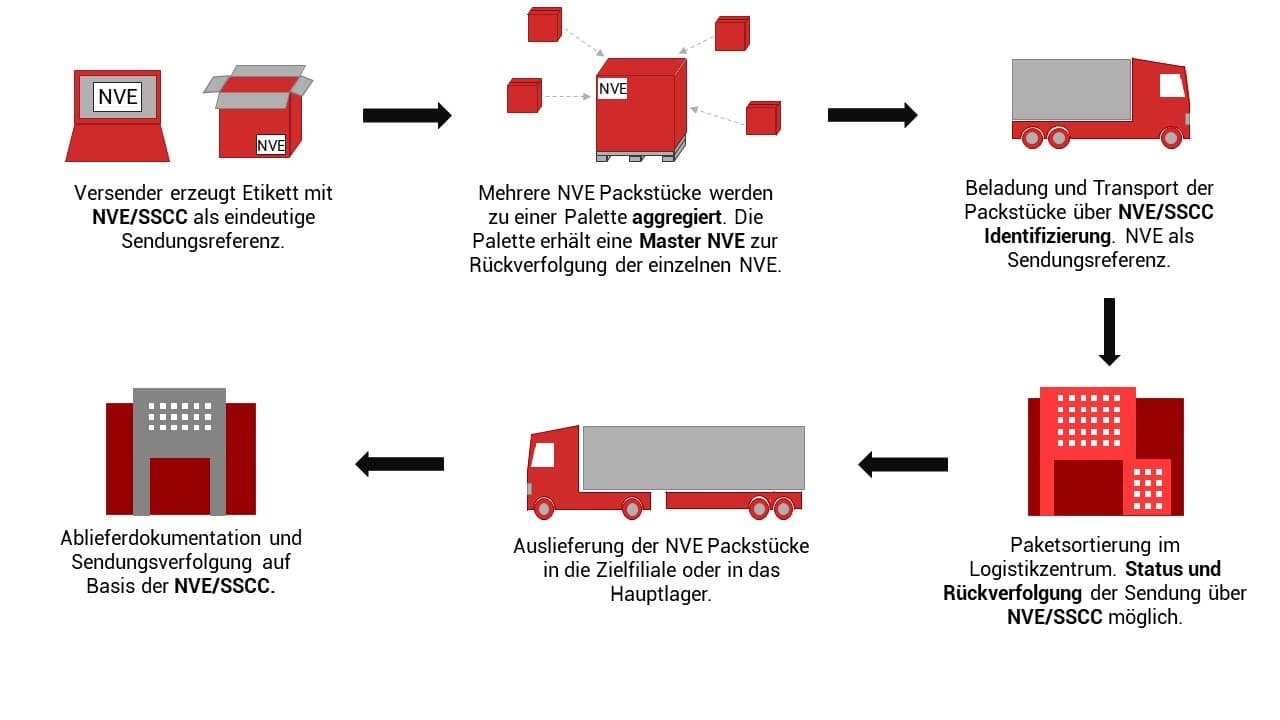

Aggregation of goods in combination with NVE / SSCC

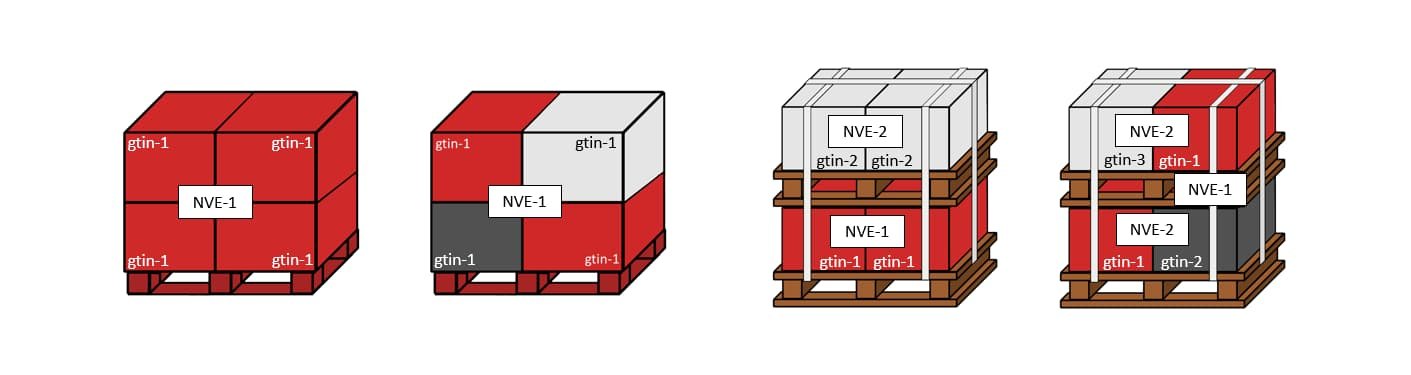

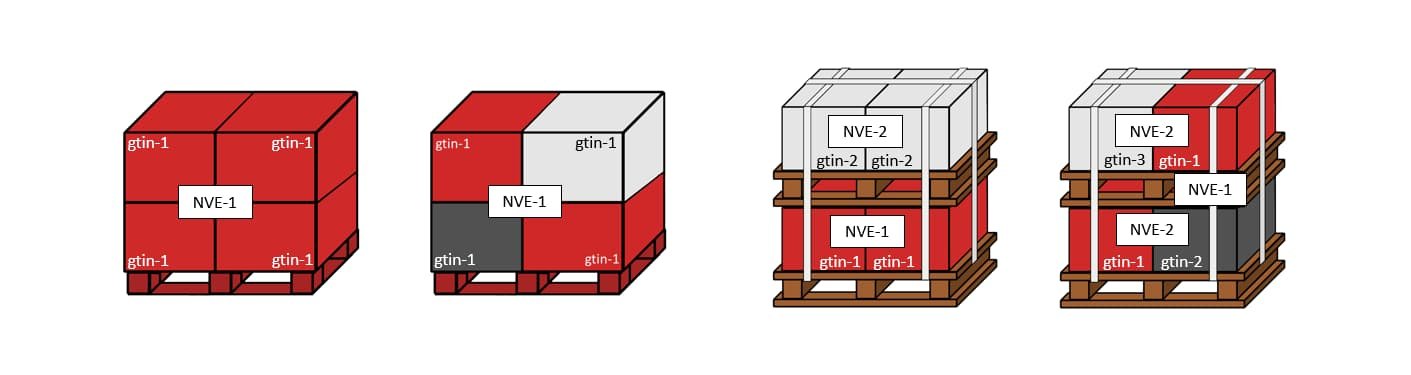

Aggregation of goods in combination with NVE / SSCCAggregation is a process in which goods or packaging types are repackaged into a next larger or several smaller packaging types. For example, several primary packagings are repackaged into one secondary packaging or one tertiary packaging into several secondary packagings. Aggregation of several packaging types onto one load carrier is also possible.

In order to link this process with DESADV, it is necessary to map the packaging structure taking into account the NVE codes. For this, the logic of the aggregation must be extended to the NVE. In this way, several NVEs can be hierarchically combined under a single NVE. The resulting NVE is called the master NVE because it is ordered over the aggregated NVEs. This hierarchical arrangement of the NVEs allows a physical packing structure to be digitally represented and used accordingly for the creation and dispatch of the DESADV.

This makes it clear which primary packagings are in which secondary packaging. An assignment of the Primary packagings NVE to the Secondary packagings Master NVE can be made by barcode scanning of the NVE and then of the Master NVE, in order to be able to map the NVE hierarchy optimally and to maintain all NVE information accordingly. Since all NVE information is contained in the master NVE, this information can be retrieved by barcode scanning. This information on aggregation and the NVE hierarchy must also be transmitted with the electronic shipping notification.

NVE / SSCC at DESADV transmission

NVE / SSCC at DESADV transmissionThe dispatch of the despatch advice notifies recipients, such as retailers, of the dispatch of goods. The supplier is responsible for the complete and correct content of the shipping notification, even if commissioned logistics service providers should create and send the shipping notification. Therefore, suppliers must ensure that the logistics service provider receives all information necessary for the shipping notification.

The ideal form of delivery notification is the DESADV electronic delivery notification. The main advantage of the electronic notification is the digital availability of important information, such as GTIN, quantities, MHD or batches of expected deliveries. Recipients of the despatch advice have the possibility to plan processes and personnel optimally. To ensure that there is sufficient time for preparation, the supplier and retailer must set a deadline by which the shipping notification must be submitted before the shipment arrives. The NVE / SSCC is transmitted with the despatch advice so that goods can be checked, processed and prepared before delivery. Through the DESADV with the NVE / SSCC, the building trade company can link the despatch advice with the delivering packages in order to identify the contents of the delivery.

For the transmission of the DESADV message different application possibilities can be used. It is important to note the assignment of delivery and delivery message as well as of the delivery to the means of transport / transport unit. Thereby a delivery message DESADV can reference exactly one or even several means of transport / units; vice versa several delivery messages can reference exactly one order.

For the transmission of the DESADV message different application possibilities can be used. It is important to note the assignment of delivery and delivery message as well as of the delivery to the means of transport / transport unit. Thereby a delivery message DESADV can reference exactly one or even several means of transport / units; vice versa several delivery messages can reference exactly one order.

Exactly can be:

Delivery structuresIn the DIY industry, the delivery of orders to the DIY retailer can be different. Accordingly, the handling of the processes is different and the requirements for the NVE / SSCC also turn out to be somewhat different.

Supply from central warehouse

The simplest type of delivery is the delivery to the central warehouse. On the basis of a purchase order, the supplier delivers the goods to the central warehouse of the retailer. Since the supplier only needs to know the central warehouse as the recipient of the goods, he does not need to deliver the orders to another address.

Any further distribution of the goods takes place internally from the time of delivery, which means that the retailer divides the orders among the various DIY stores. For the sake of simplicity, the goods are delivered in unmixed full pallets or sandwich pallets. The NVE / SSCC on the transport label and the DESADV including the NVE are used for quick identification of the goods. To determine the contents of a full pallet, the NVE is recorded so that the hierarchical structure is clear. In the case of a sandwich pallet, it applies in addition to the master NVE also recognizable for each individual layer.

Direct store delivery

Another type of delivery is direct store delivery (also known as drop shipment). In this case, the supplier does not deliver to the retailer´s central warehouse, but delivers directly to the individual stores / sales outlets of the DIY store without any detours. The processes remain the same for the supplier as for delivery to the central warehouse, the only difference being the pallets delivered.

Mixed pallets are often delivered instead of sandwich pallets or single-grade full pallets. Notification of delivery is also made by DESADV incl. NVE / SSCC.

Cross docking

Cross docking offers another possible type of delivery, where the delivery is not made directly to the final recipient, but where the orders for several final recipients are delivered bundled at a cross docking point. With cross docking, it is important to distinguish between two different procedures.

Single-stage cross docking ensures that the supplier picks the goods according to the end recipient. Logistical units are thus forwarded unchanged to the recipient via one or more cross docking points. In two-stage cross docking, the goods are picked on a cross docking basis and delivered to the cross docking point. The end recipient-related picking then takes place at the cross docking point before the shipments are forwarded unchanged directly or via further cross docking points to the end recipient.

COSYS solutions for the DIY industry with NVE support

COSYS offers a wide range of software solutions for the DIY industry and DIY stores. COSYS solutions are available in different solution packages, which include software, hardware and related services. Thanks to a wide range of software modules, all conceivable business processes can be digitally mapped by means of mobile data collection and thus made more transparent. OneInterface to ERP system allows on top a seamless data exchange between COSYS software and your enterprise resource planning. Also the use ofNVE codes from for exampleProAlpha or other ERP systems is possible.

NVE picking is particularly interesting for the DIY sector, but it is only a small part of the wide range.

In COSYS´ own back-end theCOSYS WebDeskThe recorded data can be managed and post-processed in WebDesk. By regularly recording the article codes in various work steps, WebDesk can ensure seamless tracking of the flow of goods.

Warehouse Management System Solutions:Transportation Management System Solutions: